Keep dust and water out. Two digits define solids and water. IPX9 is the IEC high pressure jet test. Vehicle specifications often quote IP69K which aligns with IPX9 in practice.

Buyers often arrive with a standard in mind. This page explains the codes people ask for across machine building, electrotechnical, and construction. We translate each requirement into practical design choices, suitable materials, and documentation. Then we cut and machine parts to drawing and supply a Certificate of Conformity.

Keep dust and water out. Two digits define solids and water. IPX9 is the IEC high pressure jet test. Vehicle specifications often quote IP69K which aligns with IPX9 in practice.

Impact resistance for enclosures and windows. Classes map to joule energy. IK10 corresponds to twenty joules using standardized hammers.

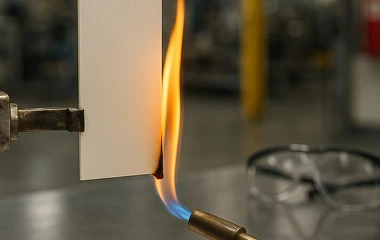

Material flammability classes such as HB V 2 V 1 V 0 and 5V. Results depend on resin and thickness. Useful for device and panel parts that require flame performance.

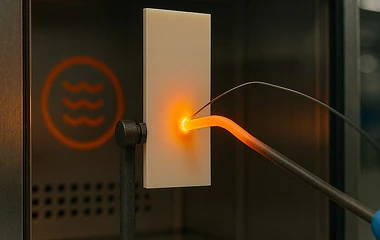

Simulates contact with hot elements to assess ignition risk for insulating plastics used in electrical equipment.

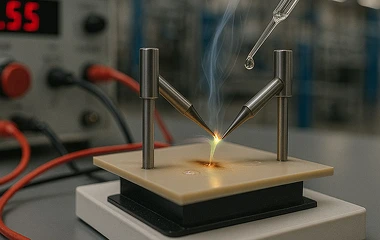

Comparative Tracking Index for insulating plastics. Choose CTI class to manage creepage and clearance around live parts.

Heat resistance check for parts in electrical equipment. Often verified at one hundred twenty five degrees Celsius depending on product standard.

Substance compliance for electrical and electronic equipment and for chemicals in the EU. We can provide declarations with shipments.

Plastics for food contact are governed by EU rules. Tell us the medium temperature and exposure time so we can advise a suitable grade and provide documentation.