What CTI Measures

Resistance To Surface Tracking

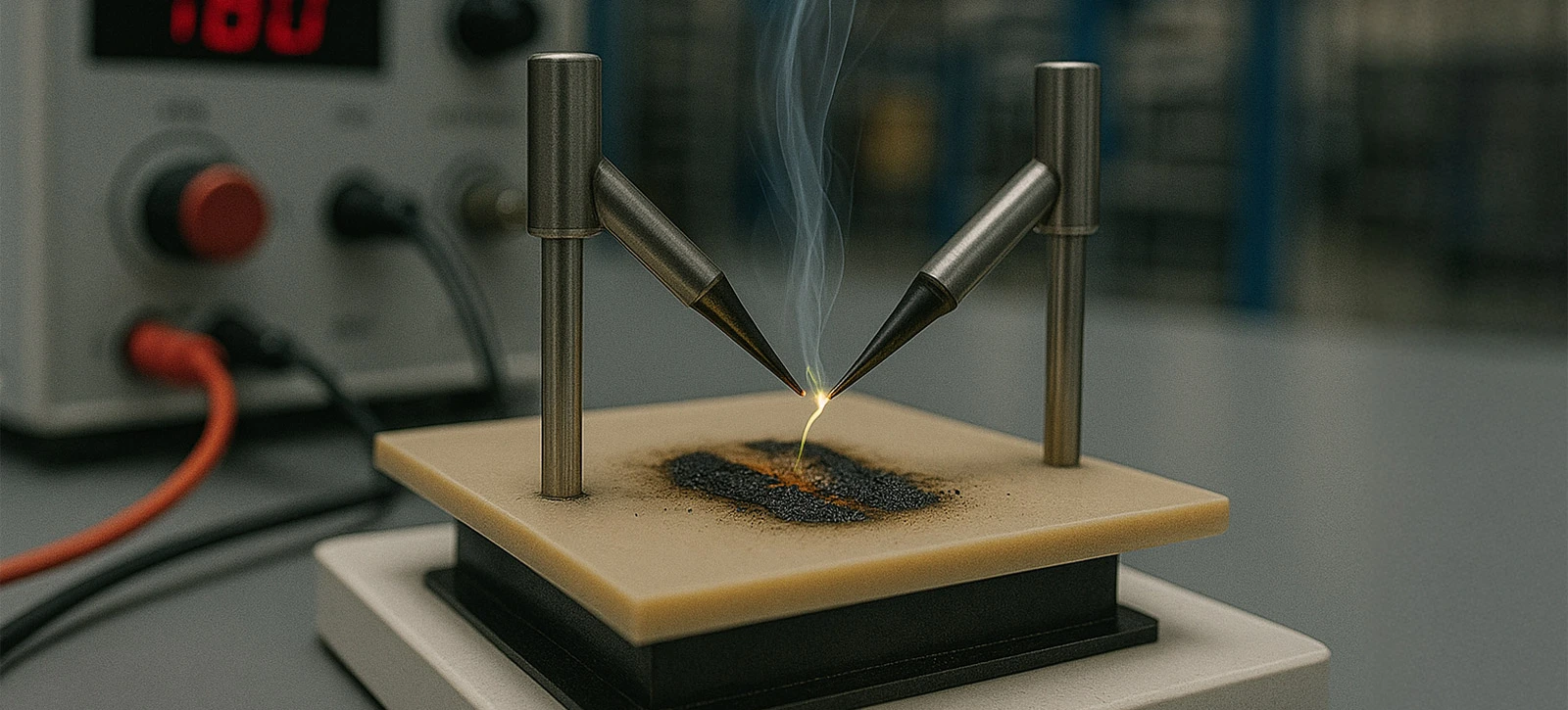

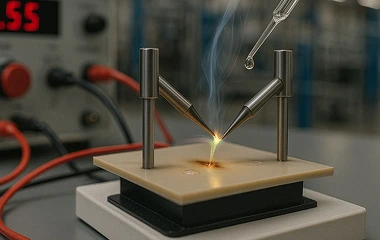

CTI is determined by a standardized test that applies a contaminant and voltage to the material surface. The measured value places the material into a CTI class. A higher class indicates greater resistance to tracking. Use CTI together with creepage and clearance design rules from your product standard. We can help align material choice with your required class.