Polycarbonate Sheet Supply

Clear, UV-protected, hard-coated and coloured formats cut to size.

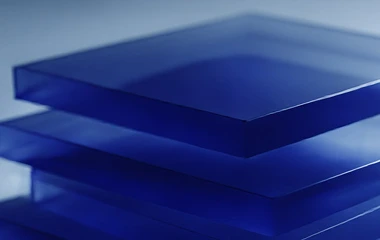

We stock a wide range of solid PC sheets for guards, covers and transparent panels. Options include UV-protected grades for outdoor use, hard-coat for improved scratch resistance and coloured/opal diffusing sheets for lighting and visual communication. Order standard formats or request cut-to-size with dependable European lead times.