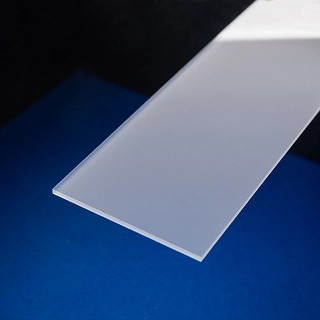

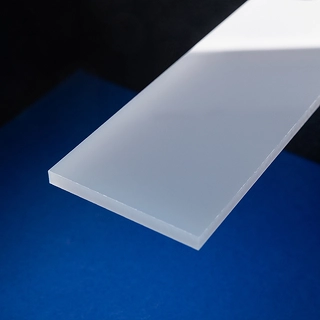

Superior Chemical Inertness

Polypropylene is virtually impervious to many organic solvents, degreasing agents, and electrolytic attacks. This makes it the primary material for chemical tank linings and laboratory equipment. Unlike metals that corrode or other plastics that might degrade, PP maintains its structural integrity when exposed to harsh acids and bases. For inspection covers requiring higher transparency, compare this with our Polycarbonate sheets.