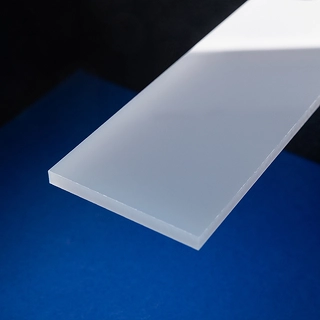

Engineered for Structural Integrity and Chemical Defense

PPH is the rigid backbone of the polypropylene family. By utilizing a 100% propylene monomer structure, this material achieves a high crystalline state, resulting in a product that is significantly stiffer than standard copolymers. This makes it the ideal candidate for load-bearing industrial structures where minimal deflection is required under thermal or mechanical stress.

Chemical & Corrosion Resistance

In the world of aggressive chemistry, PPH stands as a formidable barrier. It is practically impervious to most acids, alkalis, and saline solutions. This inert nature makes it the standard for electrolytic plating baths, chemical storage vessels, and pickling tanks where metal alternatives would succumb to corrosion. It is an essential component for the chemical processing and wastewater treatment industries.

Thermal Stability

PPH outperforms its copolymer counterpart in heat-intensive applications. It can withstand short-term temperature spikes and maintains a continuous operating temperature around $100^\circ\text{C}$. This thermal resilience prevents warping and ensures the dimensional stability of fabricated components in hot-wash environments or industrial steam-cleaning processes.

Processing & Fabrication

This material is optimized for high-strength welding. It can be joined using hot-gas or extrusion welding techniques to create airtight, leak-proof seams for tanks and enclosures. While it does not support traditional adhesive bonding, its excellent machining properties allow for high-precision CNC routing and drilling to tolerances of $\pm 0.1 \text{ mm}$.

Practical Applications

Ideal for heavy-duty industrial environments. Use PPH to fabricate chemical tanks, laboratory exhaust hoods, and ventilation systems. Its FDA compliance also allows for extensive use in pharmaceutical processing and industrial food production lines where hygiene and chemical washdowns are frequent.

Availability

- Standard Size: 2000 x 1000 mm / 3000 x 1500 mm

- Thickness Range: 2mm to 30mm

- Service: Available as full sheets or custom CNC cut-to-size panels.

Er is geen voorraad beschikbaar

Plastic Classification Certificates and Test Standards

Information for all Plastic Classifications, Certificates and Standards is available for download in the following tab. Also see our informative page on classifications and standards here.

Chemical & Fabrication Compliance

| Chemical Resistance | ISO/TR 10358 (Rated: Excellent) |

| Structural Welding | DVS 2207 / DVS 2205 (Compliant) |

| Environmental Safety | REACH & RoHS Compliant |

Food, Water & Electrical Safety

| FDA Compliance | 21 CFR 177.1520 (Food Grade) |

| EU Regulation | No. 10/2011 (Migration Tested) |

| Electrical Insulation | UL 746C / IEC 60243-1 |

Mechanical & Thermal Safety (ISO Standards)

| Density (ISO 1183) | 0.91 g/cm³ |

| Tensile Strength (ISO 527) | 33 MPa |

| Vicat Softening (ISO 306) | 150°C |

Fire Behavior & Specialized Ratings

| UL 94 Rating | Class HB (Horizontal Burn) |

| Explosion Safety | ATEX (Available for Conductive Grades) |

Note: PPH is a combustible material. For applications requiring self-extinguishing properties (UL 94 V-0) or FM 4910 cleanroom compliance, please consult our technical team for specialized grade availability.

Er zijn geen certificaten beschikbaar