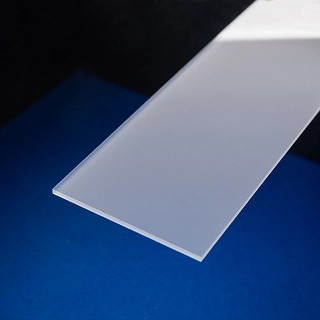

The Tougher Polypropylene for Dynamic Environments

PPC is the result of adding approximately 5-15% ethylene during the polymerization of propylene. This process creates a "random" or "block" copolymer that interrupts the crystalline structure, making the material less rigid but far more capable of absorbing energy without cracking. While PPH is the king of stiffness, PPC is the master of impact survival.

Living Hinge Performance

One of the most notable engineering characteristics of PPC is its fatigue life. It is the premier material for "living hinges"—thin sections of plastic that act as a mechanical hinge. Because of its ductile nature, a PPC hinge can be flexed hundreds of thousands of times without failing, making it essential for custom-molded cases, protective lids, and integrated industrial flaps.

Low-Temperature Durability

Standard plastics often reach a "glass transition" point in cold weather, becoming fragile and prone to shattering. PPC maintains its integrity in refrigerated environments and winter outdoor applications. This makes it an essential material for the transport industry, cold-storage facility cladding, and outdoor equipment housing.

Chemical Resistance & Fabrication

Despite its increased toughness, PPC retains the legendary chemical resistance associated with the polypropylene family. It is easy to fabricate using standard woodworking and metalworking tools. For structural integrity, it can be welded using the same techniques as PPH (using PPC-specific welding rod) to create high-strength, leak-proof joints in containers and industrial ducting.

Practical Applications

PPC is widely used where mechanical "give" is required. Common applications include automotive interior and exterior trim, heavy-duty storage bins, chemical spill pallets, and specialized protective guards for machines operating in unheated workshops. Its food-safe status also makes it ideal for bulk food processing containers that are handled roughly.

Availability

- Standard Size: 2000 x 1000 mm / 3000 x 1500 mm

- Thickness Range: 2mm to 20mm

- Service: Available in full sheets or custom-cut panels via our CNC service.

Er is geen voorraad beschikbaar

Plastic Classification Certificates and Test Standards

Information for all Plastic Classifications, Certificates and Standards is available for download in the following tab. Also see our informative page on classifications and standards here.

Mechanical & Fabrication Performance

| Impact Strength | ISO 179 (No Break at 23°C) |

| Welding Integrity | DVS 2207 / DVS 2205 (Compliant) |

| Material Spec | ASTM D4101 (Classification System) |

Hygienic & Environmental Standards

| FDA Compliance | 21 CFR 177.1520 (Food Grade) |

| Moisture Absorption | <0.01% (ISO 62) |

| Sustainability | Recyclable (Code 5) |

Thermal & Electrical Safety

| Service Temp | -20°C to +80°C |

| Vicat Softening (ISO 306) | 145°C |

| Electrical Insulation | IEC 60243-1 (Dielectric Strength) |

Fire Behavior

| UL 94 Rating | Class HB (Horizontal Burn) |

| EN 13501-1 | Class E |

Note: PPC is a combustible material. For environments subject to explosive hazards, antistatic or conductive PPC grades are required to meet ATEX directives. Contact SRT Plastics for specific material data.

Er zijn geen certificaten beschikbaar