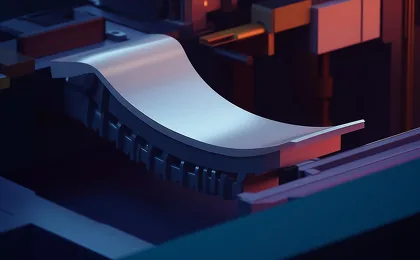

Precision in Heated Bending

Controlled heating ensures accurate and consistent bends.

With heat bending, thermoplastic sheets are selectively heated along defined lines, making them pliable for accurate shaping. Once cooled, the material holds its new form with durability and consistency. Ideal for machine guards, panels, and enclosures requiring neat, repeatable bends.