Shaping Plastics with Precision

Controlled heating for smooth and uniform curves in sheet materials.

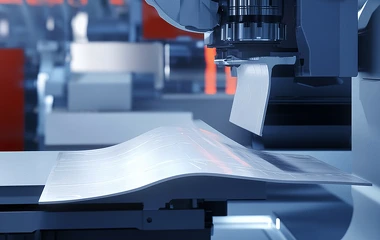

Drape forming provides accuracy and repeatability by heating plastic sheets until they reach forming temperature and then shaping them over moulds. The result is smooth, durable parts with clean curves and angles, ideal for functional housings, protective covers, and design-focused elements.