Forming Plastics into 3D Shapes

Transform flat plastic sheets into durable, lightweight and functional parts.

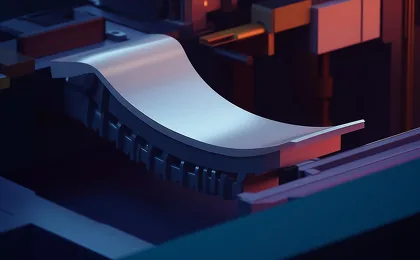

Vacuum forming changes flat sheets into three-dimensional shapes by heating and shaping over a mold. This process is ideal for lightweight panels, protective covers, and casings. It combines design freedom with efficiency, making it suitable for both prototype work and industrial production.