Clean and Precise Finishing

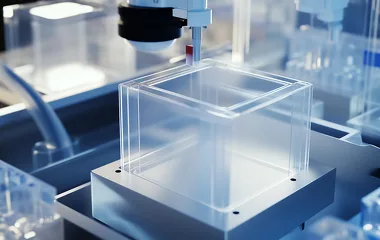

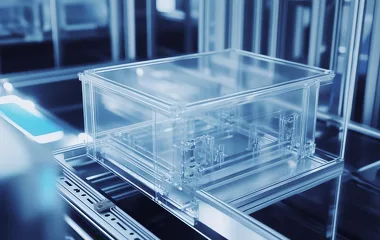

Bonding avoids screws or rivets, ensuring smooth and seamless results.

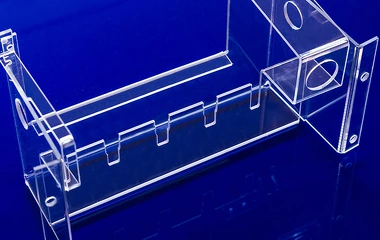

Bonding enables invisible connections, producing sleek components without drill holes or fasteners. The method improves aesthetics and allows designers to create clear covers, transparent housings, and panels that combine visual quality with functional strength.