Precision Plastic Welding Solutions

Consistent quality for thermoplastic assemblies

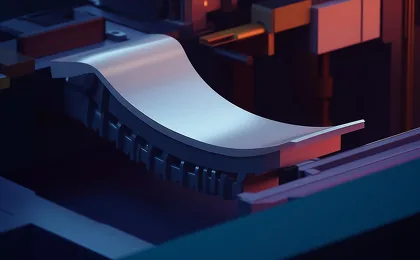

Plastic welding creates solid, durable bonds by heating and joining compatible thermoplastics. This method ensures consistent performance across applications, from housings and containers to custom technical components. With precision equipment and skilled operators, we provide welding solutions that match your exact specifications.