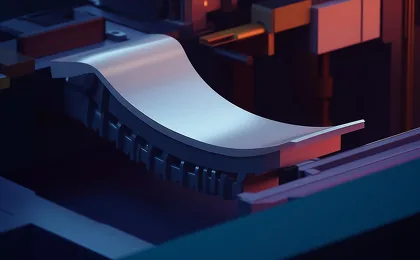

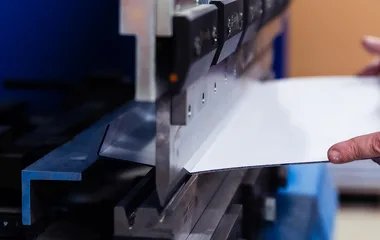

Quick and Simple Fabrication

Cold bending offers fast, practical shaping for thin thermoplastic sheets.

Cold bending allows plastics to be bent along straight lines without heating. This reduces production time while still ensuring functionality and accuracy. It is especially suited for lightweight covers, guards, and panels used in various industrial applications.