Choosing a fabrication partner is about more than machines and materials. In this article, we explore the six traits that define a reliable plastic fabrication partner and explain why collaboration, flexibility, and in-house expertise make all the difference in industrial projects.

Why the Right Fabrication Partner Matters in Industrial Projects

In industrial environments, choosing the right materials is only part of the equation. Success often depends on how those materials are processed, shaped, and delivered. A reliable plastic fabrication partner can reduce lead times, lower production risks, and improve the overall performance of the end product.

At SRT Plastics, we support engineers, technical buyers, and project managers by offering custom fabrication services that combine material expertise with flexible production capabilities. Our approach is built on precision, problem solving, and long-term collaboration.

What to Look for in a Fabrication Partner

1. Understanding of Industrial Requirements

A good partner should understand the pressures of industrial environments. This includes knowledge of load-bearing needs, compliance requirements, hygiene standards, and the constraints of installation or assembly on-site. Generic plastic processing experience is not enough. Industrial applications demand process insight and product awareness.

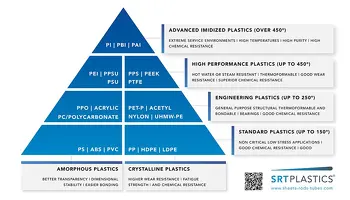

2. Access to High Performance Materials

The best fabricators are also materials experts. From impact-resistant ABS to transparent polycarbonate and flame-retardant HPL, a valuable partner will help you select the right plastic for your mechanical, thermal, and regulatory needs. They should also be able to recommend alternatives that improve cost or simplify processing.

3. In-House Capabilities for Full Control

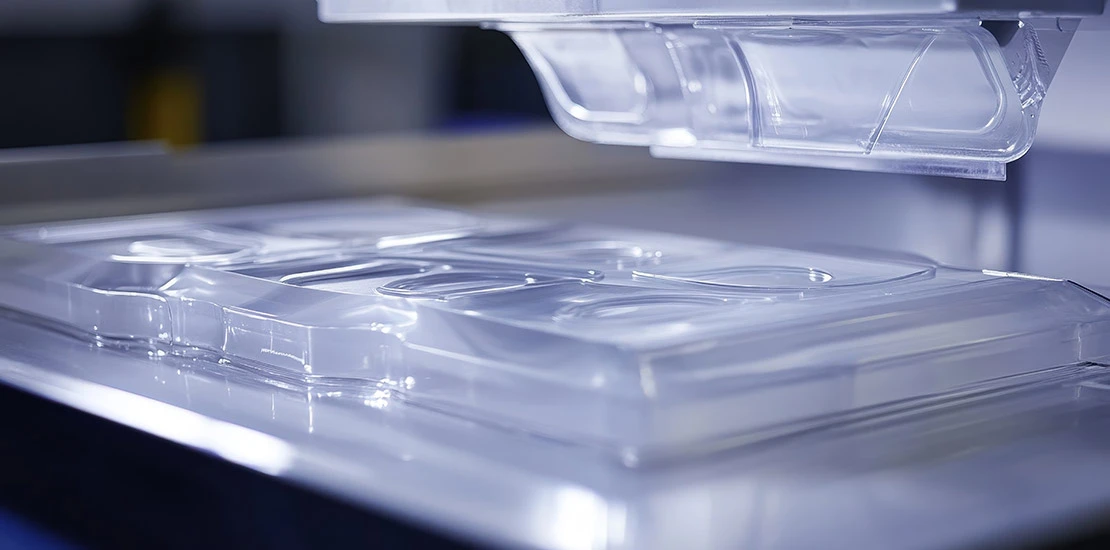

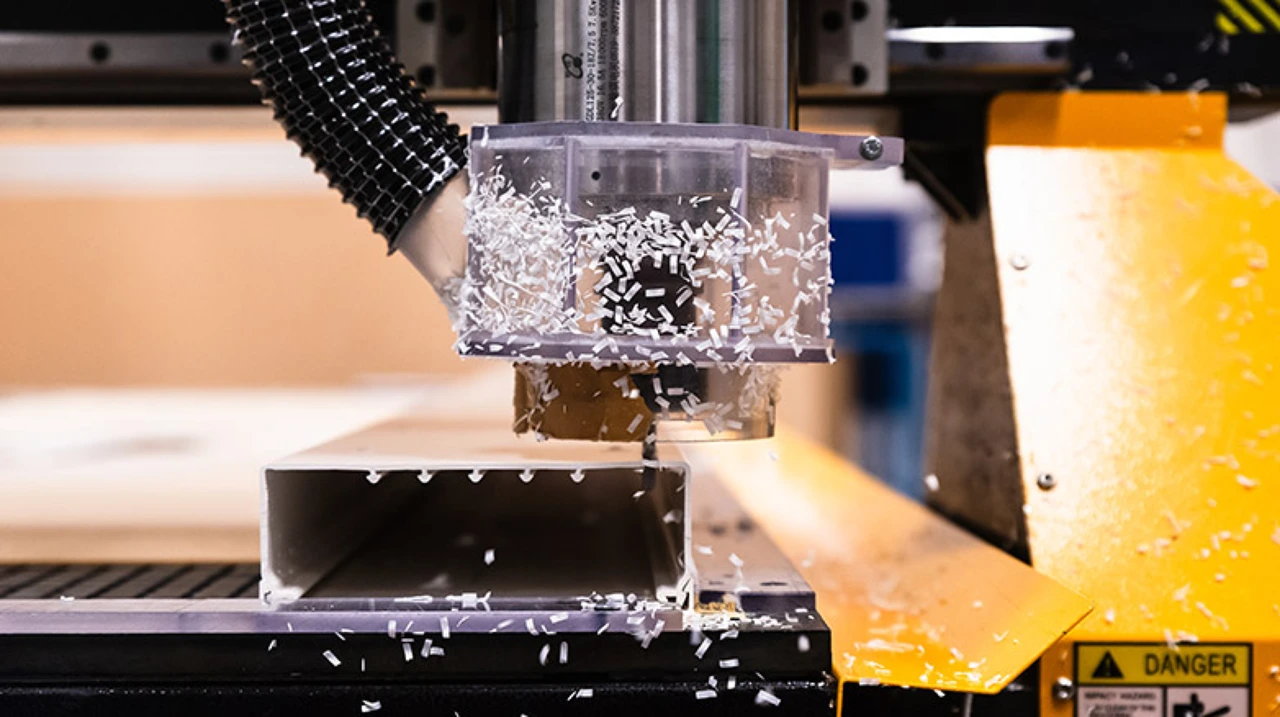

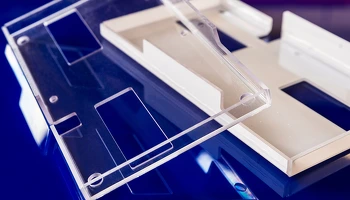

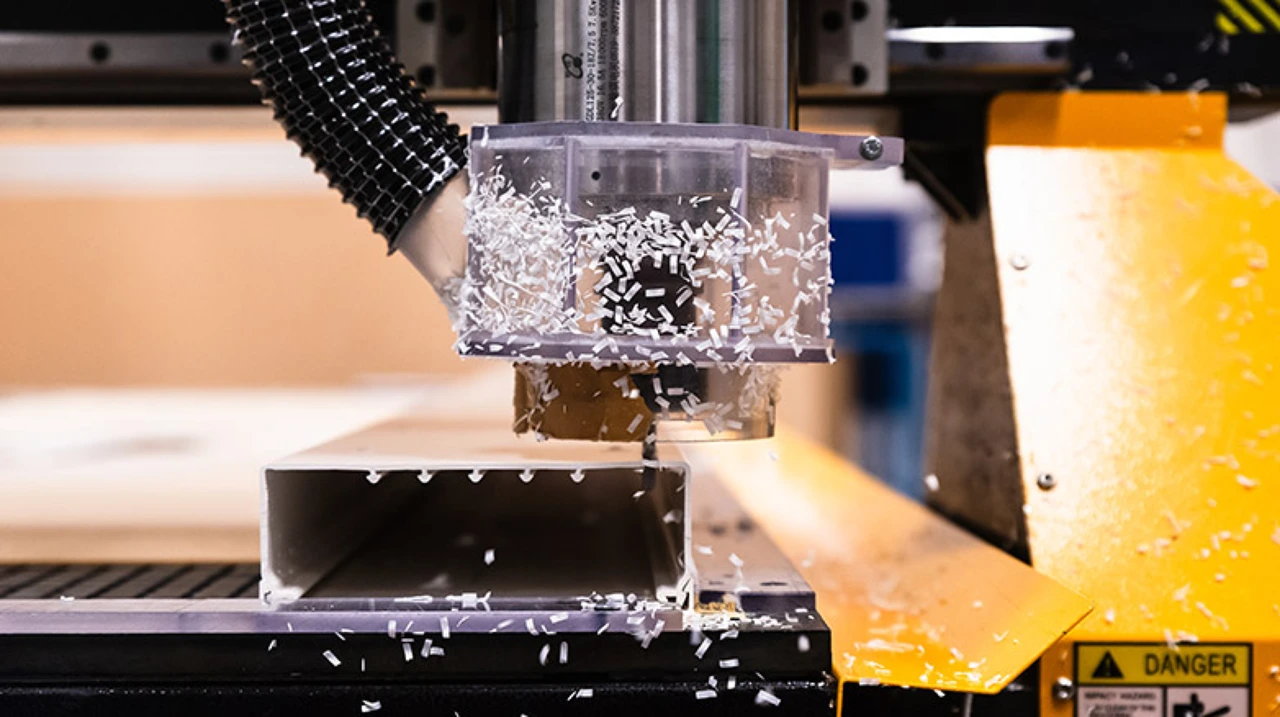

Fabrication quality improves when all steps are handled in-house. This ensures better process control, faster iteration, and fewer delays due to outsourcing. A good partner should offer cutting, CNC milling, bonding, forming, and finishing under one roof, with clear communication at every stage.

4. Experience with Custom and Low Volume Work

Industrial projects often require tailored components, one-off prototypes, or small batches. The right fabrication partner will offer this flexibility without compromising quality. They should be able to scale with your project while maintaining repeatability across versions.

5. Project-Based Thinking

Fabrication is more than cutting plastic. It involves collaborating with your engineers, understanding design intent, and considering how the component interacts with your system. A valuable partner contributes to the solution, not just the parts list.

6. Transparent Communication and Technical Support

You should not have to chase down updates or wonder whether tolerances will be met. A fabrication partner adds value when they provide clear estimates, flag potential issues early, and offer design feedback when needed. They act as an extension of your own technical team.

Why Companies Choose SRT Plastics

- Material and fabrication knowledge tailored to industrial use

- In-house CNC machining, bonding, and forming capabilities

- Support for low-volume, one-off, or prototype runs

- Fast turnaround for technical components

- Hands-on collaboration with your engineering team

Looking for a Fabrication Partner You Can Count On?

Whether you are building machines, control cabinets, safety systems, or technical housings, we help you translate ideas into durable plastic components. Our team is ready to assist with design input, material selection, and industrial-grade production.

Explore our fabrication capabilities or contact us to discuss your next industrial project.