Discover how engineered plastics like ABS, HPL, and polycarbonate are increasingly replacing metal in modern machine building. This article explores six key reasons to consider plastics instead of metal, including benefits such as lower weight, corrosion resistance, transparency, and greater design freedom. Real examples from SRT Plastics show how this shift delivers both technical and economic advantages.

Rethinking Material Choices in Modern Engineering

In today’s industrial environment, machine builders face increasing pressure to reduce weight, streamline design, and improve cost efficiency without compromising performance. One of the most effective ways to achieve these goals is by replacing traditional metal components with engineered thermoplastics.

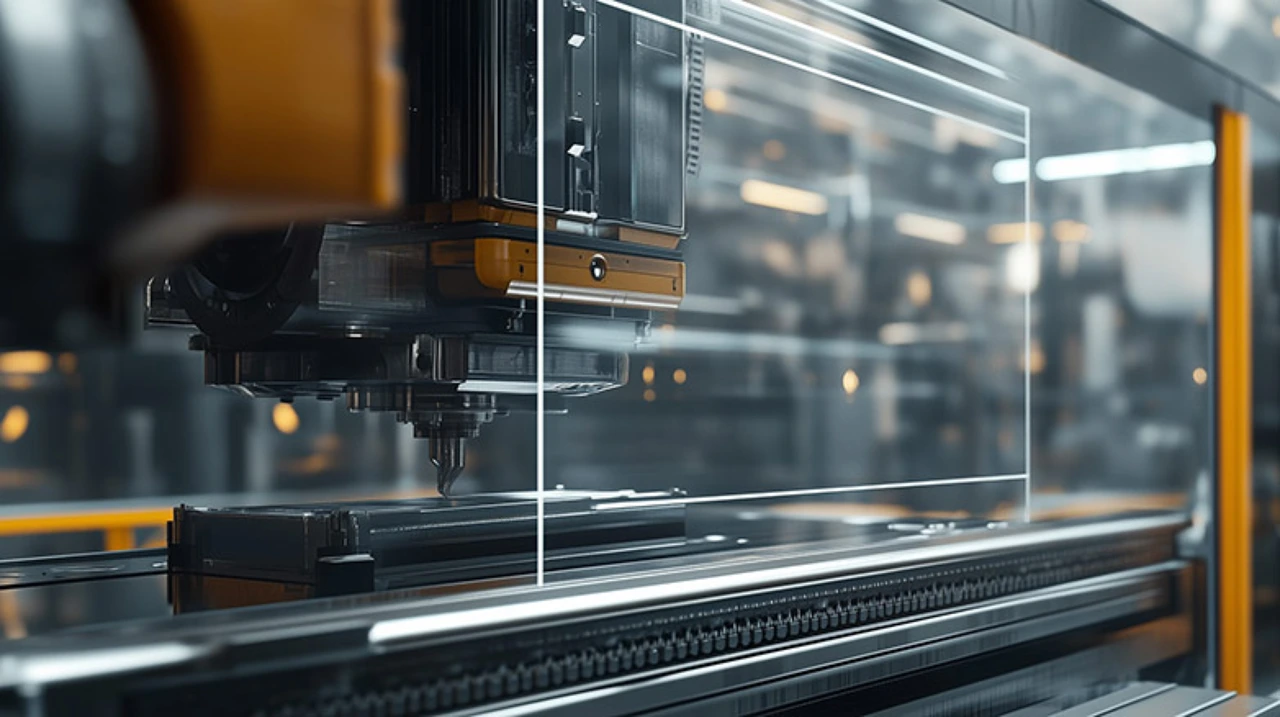

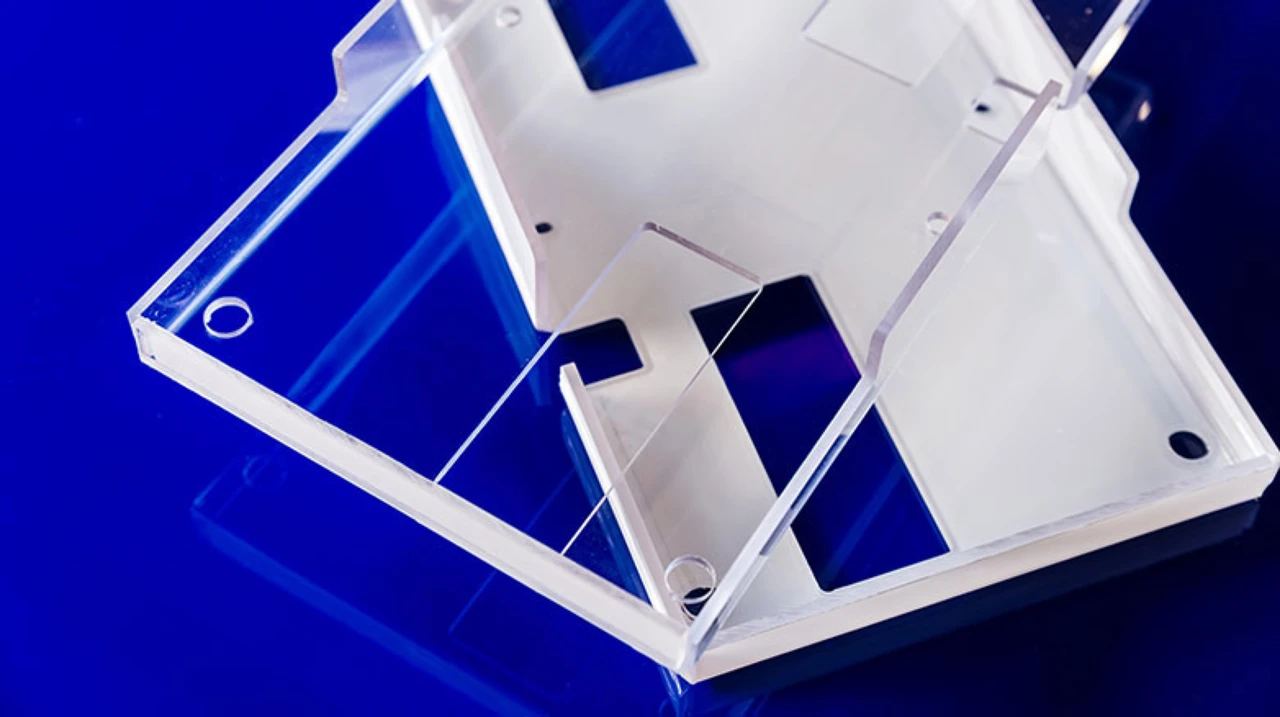

At SRT Plastics, we collaborate with OEMs, engineers, and industrial teams to develop custom plastic components that offer clear benefits over their metal counterparts. These include transparent safety guards, precision mounting panels, and durable, lightweight housings.

Why Replace Metal with Plastic?

1. Lighter Weight with Strong Mechanical Performance

Thermoplastics such as ABS, polycarbonate, and HPL provide excellent strength while being significantly lighter than steel or aluminium. This simplifies installation, reduces load on supporting structures, and cuts transport and handling costs.

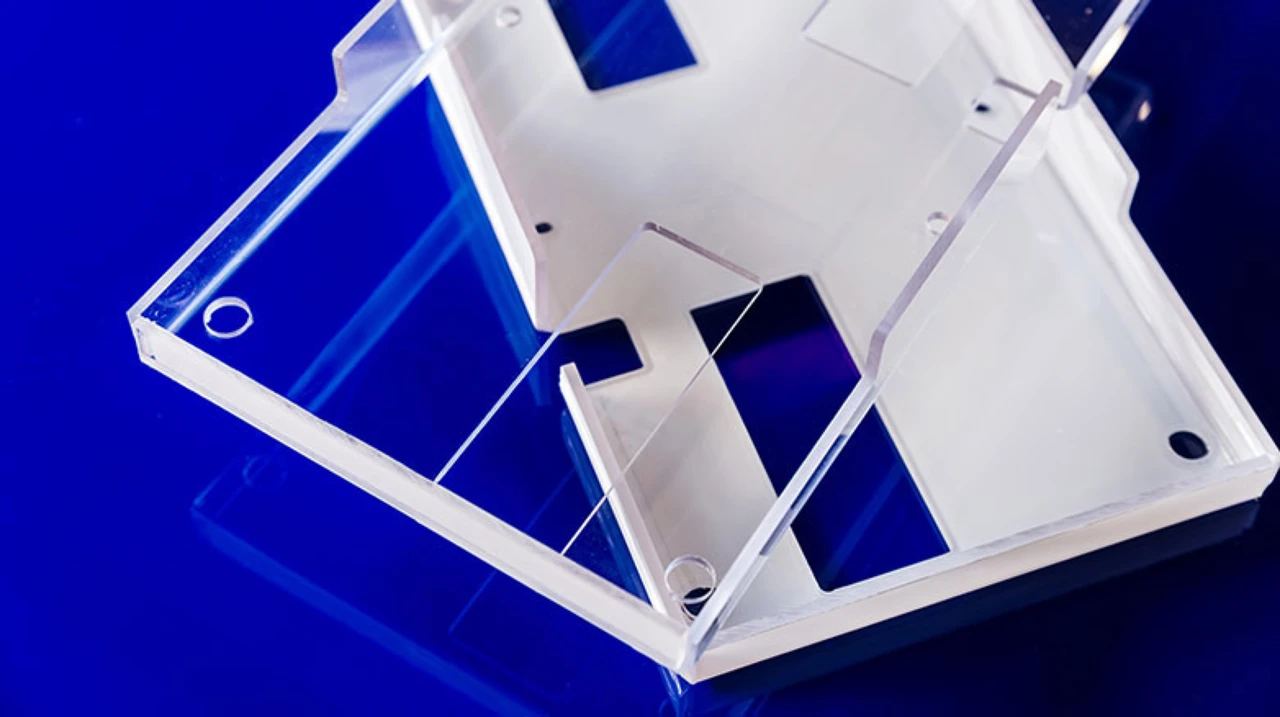

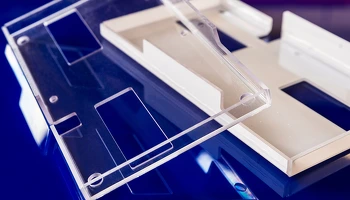

2. Built-In Transparency for Safe Visibility

Transparent materials like polycarbonate and PETG make it possible to see inside machinery without opening covers or removing panels. These plastics are perfect for protective shields and inspection panels that allow operators to monitor moving parts while keeping their hands and eyes safe.

3. Corrosion and Chemical Resistance

Plastics are inherently resistant to moisture, oils, and cleaning chemicals. This makes them ideal in settings where metal parts would require protective coatings or risk corrosion, such as food production, washdown areas, or humid environments.

4. Design Freedom and Complex Shaping

Unlike metal, plastics can be thermoformed, CNC machined, bent, or bonded into complex geometries. This enables integrated design features, smooth edges, and tailored shapes without the need for heavy post-processing or expensive tooling.

5. Electrical Insulation Without Additional Materials

Many plastics, including ABS and HPL, are natural insulators. This makes them a safer and more convenient choice for electrical enclosures, mounting panels, and switchgear applications where conductivity is a concern.

6. Lower Overall Production Costs

Plastic parts typically involve lower tooling costs, faster forming, and less secondary finishing. For short runs or custom components, plastics can eliminate the need for costly dies and reduce both time and expense throughout the production process.

When to Consider Plastics Instead of Metal

Plastic fabrication may be the better choice when your component needs:

- Visual access or operator visibility

- Lightweight but strong construction

- Resistance to chemicals or environmental exposure

- Electrical insulation or reduced fire risk

- Flexibility for custom shapes or rapid prototyping

Real-World Examples from SRT Projects

We’ve supported clients across various industries in transitioning from metal to plastic with tangible results. For example:

- Steel guards were replaced with clear polycarbonate safety covers that improved visibility while reducing weight.

- Electrical cabinets were redesigned with HPL mounting panels to simplify installation and improve insulation.

- Custom enclosures were fabricated from ABS sheets, including routing for cabling and vents.

- Transparent machine panels were delivered using PETG, suitable for food-safe environments where hygiene and visibility are critical.

Interested in more examples? View our machine building solutions and our electronics and electrical engineering solutions or visit our plastic fabrication services page.

Build Smarter with SRT Plastics

At SRT Plastics, we go beyond material supply. Our team works closely with machine builders and designers to replace outdated metal parts with innovative plastic alternatives. With in-house thermoforming, CNC machining, and assembly capabilities, we deliver ready-to-install components that meet industrial standards and improve performance.

Contact us today to discuss your application or request a consultation with one of our technical specialists.