Selecting the right plastic for your industrial enclosure helps ensure long-term protection, performance, and cost-efficiency. This article outlines six key factors to consider, including impact resistance, insulation, and hygiene requirements. It also compares popular materials like ABS, polycarbonate, HPL, and PETG to help guide your decision.

Why Material Choice Matters in Industrial Enclosures

Industrial enclosures play a vital role in protecting electrical systems, control units, instrumentation, and other sensitive components from environmental, mechanical, and electrical hazards. Choosing the wrong material can lead to system failure, safety issues, or excessive maintenance costs. Selecting the right plastic is not just a technical decision. It is a strategic one.

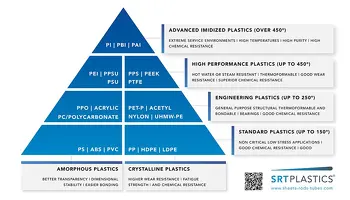

At SRT Plastics, we support engineers and procurement teams in selecting and fabricating enclosures using high-performance plastics such as ABS, HPL, polycarbonate, and PETG. Each material has specific advantages depending on the application and the environment.

Key Factors to Consider When Selecting a Plastic

1. Environmental Resistance

Will the enclosure be exposed to moisture, dust, UV radiation, chemicals, or temperature extremes? For outdoor use or chemically exposed environments, materials like polycarbonate or UV-stabilised ABS are strong candidates. HPL is also highly suited for tough industrial settings where durability and wear resistance are critical.

2. Mechanical Impact Resistance

Enclosures in production facilities or mounted on mobile machinery often require protection from physical impacts. Polycarbonate is known for its virtually unbreakable performance. ABS is another strong option that combines impact resistance with stiffness and shape retention.

3. Electrical Insulation

Electrical housings must provide insulation to reduce the risk of short circuits. ABS and HPL are naturally non-conductive, making them excellent materials for mounting plates, junction boxes, and enclosures in high-voltage systems.

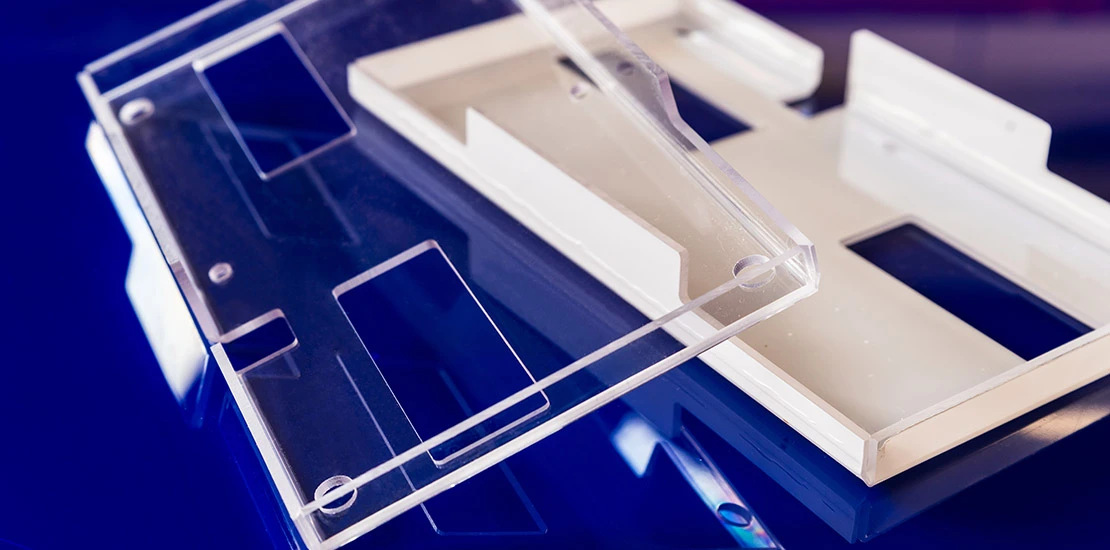

4. Transparency Requirements

Some applications require operators to monitor equipment visually without opening the enclosure. In these cases, clear plastics like polycarbonate or PETG allow visibility while maintaining full protection. These materials are frequently used for inspection windows, control panels, and safety guards.

5. Machinability and Formability

Projects that involve custom shapes, ventilation slots, mounting features, or complex contours benefit from plastics that are easy to machine or thermoform. ABS and HPL are highly suitable for CNC milling, drilling, and bonding. Polycarbonate and PETG can be formed into smooth curves and rounded panels using heat-based techniques.

6. Regulatory Compliance

Certain industries require enclosures to meet strict standards for hygiene, fire resistance, or food safety. PETG is a suitable choice for hygienic areas, while flame-retardant ABS variants are available for use in environments with higher fire safety requirements. These materials can be fabricated in controlled conditions where necessary.

Popular Material Options for Enclosures

- ABS: Rigid, durable, and easy to machine. Well suited for control boxes, low-voltage panels, and general-purpose housings.

- Polycarbonate: Transparent, impact-resistant, and resistant to outdoor conditions. Ideal for inspection windows and protective covers.

- HPL (High Pressure Laminate): Strong, flame-retardant, and non-conductive. Commonly used in switchgear panels and mounting boards.

- PETG: Clear, formable, and compliant with hygienic standards. Used in curved viewing panels and food-safe environments.

Need Help Choosing the Right Material?

Choosing the right plastic depends on many factors, including function, exposure, and compliance. Our team is available to help you compare materials and fabrication options based on your specific enclosure design and application.

Explore our fabrication services or get in touch to discuss your enclosure project with one of our specialists.