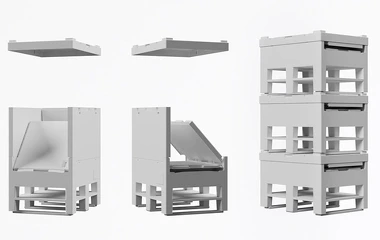

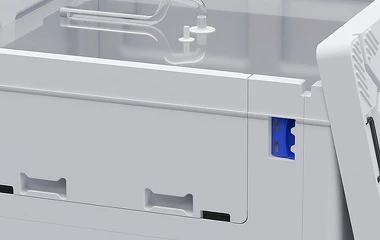

Sterile Protection for Cleanrooms

Containers designed for aseptic handling and contamination control.

Our bio-pharma containers are engineered for sterile environments, protecting fluids, powders and parts from contamination. Smooth surfaces simplify cleaning and sterilisation, while resistant materials ensure durability. Each container supports compliance with GMP, EU directives and UK cleanroom regulations.